SISENER,as a department specialized in thermochemical processes that includes the specialties of processes, piping, instrumentation, programming and Scada, civil, structures, electrical, fluodynamic studies, etc., all of them oriented to the treatment and recovery of waste. SISENER's participation in Greenval or in other third-party projects also qualifies us as technology developers, scaling it to an industrial size.

BLACKCYCLE PROJECT

Our group collaborates with the Michelin company and 11 other partners in this project based on the circular economy and whose objective is the development of new technologies for the recovery of the materials that make up end-of-life tires, thus allowing their reuse in new technical applications. of high added value.

In 2020 this project received support from the European H2020 Financing Program (ID: 869625). Know more.

PYROCRACK

Our company and the Instituto de Carboquímica launched, with European support, a new method for treating solid urban waste. The technology developed, Pirocrack, consists of the combination of a pyrolysis process combined with thermal cracking.

This project has received support from the European H2020 Funding Program in Phase I (ID: 849623).

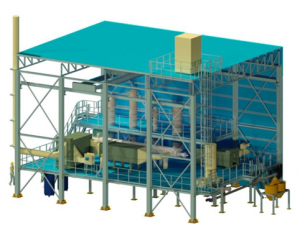

SCRAP TYRES TREATMENT PLANT (Zaragoza, Spain)

WASTE TO FUEL: Scrap tyres treatment plant to obtain fuel, gas and carbon black. Zaragoza (SPAIN). 2014-2015.

Plant that processes 5,500 tons per year of tyre granules and production of 2,500 m3 fuel and 2,300 tons Carbon Black.

INDUSTRIAL PLASTIC WASTE TREATMENT PLANT (Lérida, Spain)

IMPLEMENTATION WASTE TO FUEL&GAS PLANT: Plastic processing plant to obtain fuel and gas inside an existing industry.

Plant that processes 3.000 Ton per year of Industrial Plastics.

Client: ELECNOR

MSW TREATMENT PLANT BY AUTOCLAVE

Implementation of the AUTOCLAVE Technology in a Municipal Solid Waste Processing Plant. SISENER is the technologist ‘s Support Engineering. Administrative projects in Argentina and California and operation manual.

Client: ECOHISPANICA

BIODIGESTIÓN DE PURINES

Installation for slurry treatment by anaerobic digestion, biogas generation and energy production.

Client: AMDA ENERGÍA

(For more detailed information on work area or country go to CONTACT)